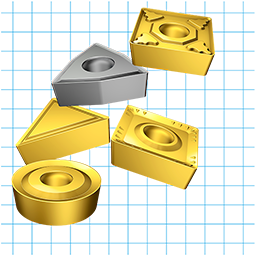

Hard MetalCemented carbide is a range of very hard, refractory wear resistant alloys made by powder metallurgical techniques. Production embraces the preparation of a powder consisting of a number of very hard metal carbides or carbonitrides, mixed with a binder powder, normally of tough and comparatively soft cobalt. The powder is applied in a pressing tool representing a mirror image of the component that should be produced. After pressing the component is being sintered in a sintering furnace at a temperature between 1300 - 1700º C, whereby the cobalt melts and bonds the carbides to a hard metal matrix. Normally sintered metal removal throw-away carbide inserts are being exposed to a number of post-treatments such as grinding, polishing, blastering and coating. Carbide throw-away inserts can generally be used for machining of all types of steels, cast iron, metals, heat-resistant alloys, plastics, rubber, stone, wood etc. |

|

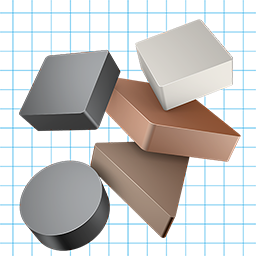

CeramicsCeramics are very hard, completely non-metallic substances, resistant to heat and abrasive wear, increasingly used as clamped indexable inserts. In many respects the manufacture of ceramics is similar to that of hard-metals (see above), including preparation of powder, pressing, sintering and post-treatments. The ceramics do not contain any metallic binder of low melting point as the case is with carbide. In comparison to carbide the ceramics are much harder and more brittle and show a considerably better resistance to abrasive wear and heat, i e high cutting speeds. Ceramic throw-away inserts can generally be used for high speed machining of most steels and cast irons, as well as very hard and abrasive work-piece materials. Some specific types are suitable for use in machining heat-resistant alloys. |

|

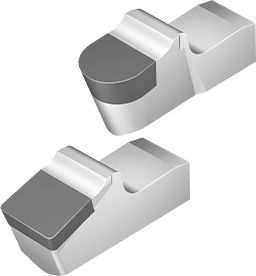

Diamond and Boron NitrideUltra-hard diamond or cubic boron nitride inserts are produced at ultra high pressures and high temperature. In especially designed presses a powder of graphite and a metallic catalyst, can be transformed to small grains of diamond, due to the ultra high pressure and temperature the mixture is exposed to. In a similar way hexagonal boron nitride can be turned into small grains of cubic boron nitride by exposing the powder to the same procedure as described above. From the small grains, a larger solid piece of polycrystalline diamond or cubic boron nitride can be achieved, by in principle repeating the procedure described above, whereby the small grains will be sintered together into a solid piece, normally sintered onto a carrier of carbide backing. The plate with the carbide backing, is made in the shape of a cylinder with low height (some mm), is cut into smaller pieces which in turn are braced onto a carbide insert. Ultra-hard diamond throw-away inserts are generally used for machining of all non-ferrous metals, plastics, rubber, hard wood, stone, chip board etc. Ultra-hard cubic boron nitride throw-away inserts are generally being used for machining very hard steel or cast iron, or for machining specific types of soft cast irons. |

|

MIRCONA

- Your Partner on Cutting Tools